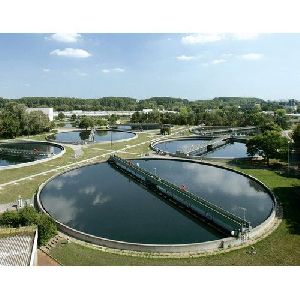

Pure Water Technology specialized in providing turnkey solutions for engineering, procurement, construction and upgrading of sewage treatment plants. We are one of the largest wastewater treatment plant contractors in the region with municipal and industrial wastewater treatment contracts involving new facility construction, expansions and modifications. Our experience Wastewater treatment plants encompasses sewer collection systems, advanced wastewater treatment facilities, residuals management and handling, odor control and air pollution and water reuse. We have significant expertise in all facets of wastewater liquid stream and solids stream treatment ranging from conventional plants for organic removals to complex nutrient removal/resource recovery processes covering scopes from compliance evaluations to turnkey delivery of completely operational facilities. We have also performed numerous industrial wastewater treatment plant design upgrades to meet client requirements. Engineering, procurement and construction management services were provided for wastewater treatment plants, including all process, mechanical, civil, electrical, and control systems. Our team engineers work closely with the clients to ensure high efficiency and reliability & to provide cost-effective solutions for their specific needs. Pure Water Technology’s range of advanced wastewater treatment technologies of Extended Aeration, Membrane Bio-Reactor systems (MBR), Submerged Aerated Filter (SAF, ) Extended Aeration Plants, Moving Bed Bio-Reactors (MBBR) provides high treatment efficiencies and lower foot-prints through designs that integrate processes. Extended Aeration Sewage Treatment Plants The purpose of activated sludge process is to biologically stabilize the oxygen-demanding material present in wastewater with aerobic microorganisms air is supplied to these basins for the microorganism. Extended aeration activated sludge is an operational mode in which the activated sludge unit process is operated at a relatively long hydraulic retention time and sludge age. The number of aeration tanks in service varies depending on the volume of wastewater being treated for the proper detention time. Mixed liquor enters the secondary clarifiers, which slows down the flow and allows the sludge to settle and produce a clear effluent. Scum is removed from the surface of the clarifiers and transferred to the digester. Advantages: Low Maintenance Low Power Consumption High Efficiency Low Cost