Welcome to T.S Global Engineers

Manufacturer / Exporter / Supplier Of Belt Ploughs, Belt Trackers, Pulley Lagging, Impact Beds, Pulleys, CoBond Belt Repair Kits

Welcome to T.S Global Engineers

Manufacturer / Exporter / Supplier Of Belt Ploughs, Belt Trackers, Pulley Lagging, Impact Beds, Pulleys, CoBond Belt Repair Kits

A belt plough provides protection to capital items within your conveyor system such as pulleys and the conveyor belt by removing any residual product on the return side of the conveyor belt. It is industry standard to install conveyor belt ploughs prior to tail, take-up or drive pulleys.

The installation of belt tracking devlces in strategic locations protects your conveyor belt and reduces the risk of potential damage to your belt. An effective tracking unit automatically reacts to change within a conveyor system and redirects the belt back to the centre of the conveyor.

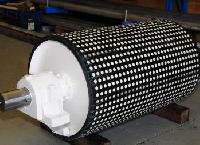

Pulley lagging protects and increases the life of your conveyor belt and pulleys by absorbing the wear between these interfacing components. In addition our design and construction improves resistance to slippage, corrosion and abrasion coupled with greater shedding capabilities.

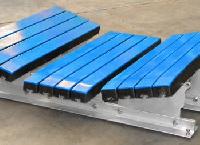

Conveyor impact beds can be installed at loading zones of any conveyor in place of traditional impact idlers. They are designed to perform two functions. The primary fuction is to absorb the forces applied onto the belt via the transfer of product from one conveyor to another. The secondary function is to eliminate belt sag encountered when using traditional impact idlers. The impact bars provide a flat and stable surface to allow effective skirt sealing which minimises the emission of dust into the environment and around the conveyor. The use of impact beds also eliminates the high cost associated with the supply and replacement of impact rollers and frames.

TS Global has the in-house capability to design, manufacture, refurbish and test run live or dead shaft conveyor pulleys to suit any application. Our engineering team has a customised pulley design program that includes 3D modelling and Finite Element Analysis (FEA) to ensure every pulley is virtually tested and fit for use, prior to manufacture. Our manufacturing is carried out using NATA approved weld procedures by qualified technicians to ensure adherence to ASNZS -1554 structural welding to ensure a quality product. Post-weld heat treatment, stress relieving and non-destructive testing on all weldments and materials are available on request. All pulleys are put through a rigorous live bench test which includes vibration analysis and thermography on our unique in-house testing facility, allowing the pulley to be guaranteed before on-site installation. Our clients are provided with a report showing the outcomes of the testing prior to installation.

The range of CoBond’s conveyor belt repair materials provide a simple, efficient and cost effective solution to repairing a damaged or torn conveyor belt. The repair kits are a 100% solid polyurethane compound for the repair of conveyor belts and linings. Used in conjunction with our primers, these provide an extremely strong repair. Key features include: Fast and easy application No need for specialist equipment High wear resistant Impact resistant Zero shrinkage 100% solids polyurethane compound Fast curing time Self mixing Engineered bond Download Brochure

Share your thoughts with other customers for T.S Global Engineers

Add Review