- IEC 61034-2Low smoke emission (only for LSZH cables)

- IEC 60332-1Flame retardant

- IEC 60332-3Fire retardant (cat. C or A according to requirements)

- IEC 60754-1Halogen free properties (only for LSZH cables)

- BS 5308 or

EN 50288-7Basic design

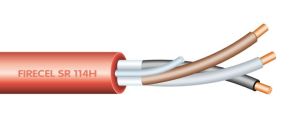

Can be used in cable tray or conduit to connect different types of thermocouple in industrial process controls, refineries, oil and gas plants. Temperature range -20 °C to +80 °C (for general use); -40 °C to +90 °C (on request). Minimum bending radius Not armoured type: 12 times the outer diameter (for conductors class 1 and class 2); 10 times the outer diameter (for conductors class 5). Armoured type: 15 times the outer diameter. Calibration and colours according to BS – DIN – NF – UNI. Stranded conductors. Galvanized steel wire braid (GSWB) or galvanized steel tape armour (GSTA). Sheath materials can be provided for excellent water, oil, hydrocarbons, UV resistance or other special performance. Cable construction Conductors Solid alloy. Calibration ANSI MC 96.1 or IEC 60584-3. Insulation PVC, PE, XLPE or LSZH thermoplastic material. Twisting The insulated cores shall be twisted in pairs/triads for a good reduction of the electromagnetic noise. Individual screen Aluminium/polyester tape, coverage >100%, aluminium in contact with tinned copper drain wire. Cabling The screened pairs are cabled with suitable non hygroscopic fillers (when necessary) and wrapped with polyester tape if required. Overall screen Aluminium/polyester tape, coverage >100%, aluminium in contact with tinned copper drain wire. Inner sheath PE, PVC or LSZH thermoplastic material. Armour Single layer of galvanized steel wires (SWA). Outer sheath PVC or LSZH thermoplastic material.